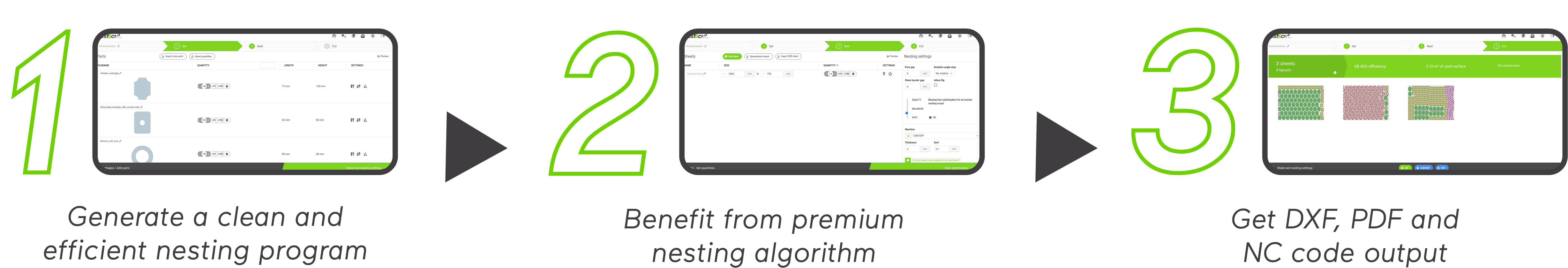

Start Optimizing & Saving

Nest&Cut is the only cloud-based 2D nesting software with premium features and 45-years expertise in nesting performance.

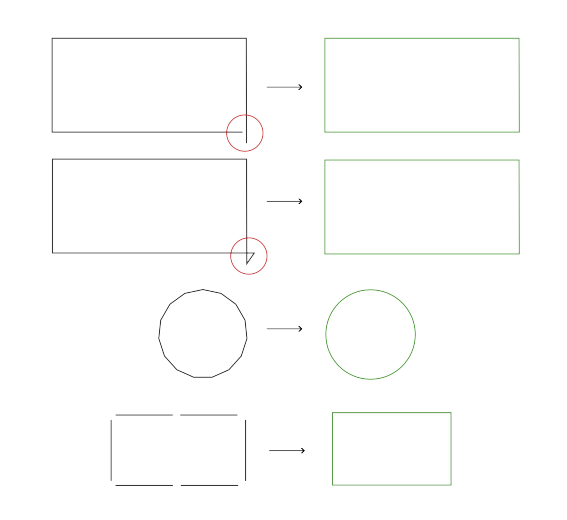

Automated import

Nest&Cut cleans and prepares your parts for efficient and easy nesting programs.

Thanks to its proprietary technology, Nest&Cut imports DXF or DWG files containing geometries and cleans up batches in series, reducing the time to prepare each nest.

Your parts have gaps, auto-intersections, poorly drawn arcs? Nest&Cut clean everything automatically. You do not have to go back to your CAD to do manual cleaning anymore.

If a DXF contains several parts, Nest&Cut smartly separated the parts or not for the best nesting.

Nest&Cut can also read and improve DXF or DWG nesting layouts that were created using another system. Identical parts are identified, even if they are rotated.

To make a quick quote or save time in production, you can do it directly in Nest&Cut by using a standard parts gallery avoiding drawing and uploading DXF time.

On a cut of 20 parts or more you can save up to 50% of time.

Over the years, Nest&Cut has evolved and you can also unfold 3D step files. You do not need another software: upload your step file, and it is done!

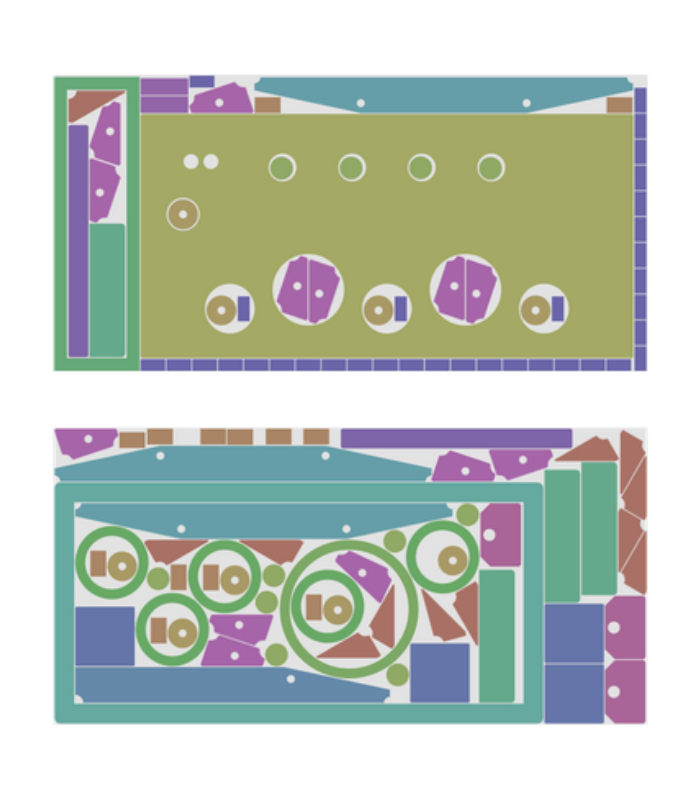

The world’s best algorithm

High efficiency that considers your business constraints.

Alma has been developing nesting algorithms for 45 years. Nest&Cut benefit from this experience and offer world-best nesting performance . It provides optimized DXF nesting layouts in a shorter time and lowers the raw material scrap ratio.

Nest&Cut chooses the best part orientation among allowed orientations. Part rotation can be customized, globally and individually. Part recesses are used to recursively nest parts in other parts, called “inside-part nesting”.

Nest&Cut performs global optimization on multiple sheets to save more material. Sheets of different sizes and shapes can be used. If you start an extra sheet, the algorithm removes it so you maintain the best efficiency.

Moreover, in order to improve productivity in case of more parts, Nest&Cut manages nesting multiplicity: the application generates a few different layouts that will be used several times.

Results tailored to your needs

Nest&Cut offers DXF, PDF and NC code output for a wide range of data processing needs.

After optimizing nesting layouts, Nest&Cut generates cutting order trajectories for a large variety of machines with an optimized sequence to reduce cutting time.

It can also output nesting layouts in DXF with an optimized cutting order of parts for a wide variety of machine post-processors including Amada, Bystronic, Flow, Hypertherm, Prima, CypCut, Esab, Gcode and many others.

At the end, you benefit from increased productivity and profit margins, with a software as easy as child’s play for your daily work!

If you have a CNC machine you can discover all the Nest&Cut CAM features.

No credit card required.