New algorithms to automatically generate NC code

Since its last update, Nest&Cut allows you to export NC code for many cutting machines. This NC code generation is based on path generation algorithms that calculate the tool path from the geometries of the parts to be successively cut and transform it into machine understandable commands. In this way, Nest&Cut automatically generates efficient and safe cutting paths that result in quality parts.

Lead-in and lead-out

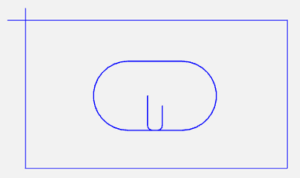

Nest&Cut will first set the lead-in and lead-out for each contour. To do this, all the parts placed are considered to avoid placing lead-ins too close to the other parts (which could damage them) while favoring those that will allow a good quality result (lead-in in the continuity of the geometry).

Lead-in and lead-out placed: the outer contour could be (un)primed in the continuation, contrary to the inner contour

Sequencing

Nest&Cut will then sequence the different cutting trajectories of the parts. This consists in defining an order that will be quick to cut, notably by avoiding round trips. This also requires considering a number of constraints, such as cutting a part placed in a hole before the hole of the enclosing part. Some additional trajectories are also added, such as vaporization trajectories or fast traverses between different cutting trajectories.

Result of the sequence of a set of parts

A translation generated for many machines

Once the sequence result is calculated, it is written in an internal intermediate format independent of the cutting machine. This allows to decouple the pure sequence part from the physical machine. Of course, this format must contain all the necessary information so that the machine commands finally generated can proceed to the cutting in the best possible way. Nest&Cut thus produces subroutines to reduce the size of the program. This internal format is finally transformed into specific instructions for the physical cutting machine thanks to our various post-processors.

Many machines supported

Since its last update, Nest&Cut allows you to export NC code for many cutting machines. You have an Amada, Hypertherm, Bystronic, Ermaksan or Esab machine? Nest&Cut includes a specific post-processor for your machine. You have another type of machine? Nest&Cut provides NC code in the standard GCode, LinuxCNC and ESSI formats, as well as DXF accepted by most NCs. Many more post-processors are to come, and you can tell us which one you need.

New features to come

We are working on the integration of many new features (loops on angles, common cut, bridges, trajectory optimizations).

Keep following us to discover the improvements of Nest&Cut!