New support for continuous technique

At Nest&Cut, we like to experiment and to introduce new functionalities based on your feedbacks. We received multiple requests about wire cutting and we decided to add experimental support for it.

We have added support for a new continuous cutting technique in Nest&Cut. This technique is useful for machines that are always cutting (i.e. they do not use a beam that you can turn off as is the case in laser, plasma or waterjet). For always cutting machines it is necessary not to cross over parts or they would be destroyed, also the trajectory must start and end on the sheet border. This cutting technique allows us to start supporting EDM (3 axis), Hot Wire (3 axis) and saw blade cutting machines.

Our algorithm optimizes crossing trajectories so that they remain as far as possible from the parts to avoid any risk of damage, and also minimizes the amount of backward movements.

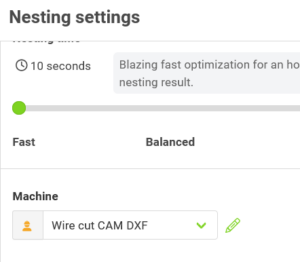

Nesting settings for wire cutting

You can already test this using the machine “Wire cut CAM DXF” you can select at “Nesting settings” stage. A DXF containing a single polyline is generated for the whole nesting, and we can provide support for any machine specific NC code language (such as G-code). Note that parts with holes are not currently supported.

We hope this will make Nest&Cut more convenient to users that have this kind of machines. This new cutting technique is in beta version, should you encounter problems or have any suggestion please contact us.