Nest&Cut algorithms offer qualitative nesting exports & cutting orders ready for your cutting machines. Experience right now the best lightweight CAD/CAM web application.

Make CAD/CAM simple & automated

With Nest&Cut we want to make CAD/CAM simple and automated, with all the CAM functionalities you need. This means that you will find all the CAM feature you need, whether you are using CNC, laser cutting, oxy cutting, plasma, waterjet cutting and many others.

Nest&Cut will automatically add all the CAM feature to make you save time. Our CAM algorithms will optimize the sequence and trajectories, based on the list of CAM features you activate with one-tick options.

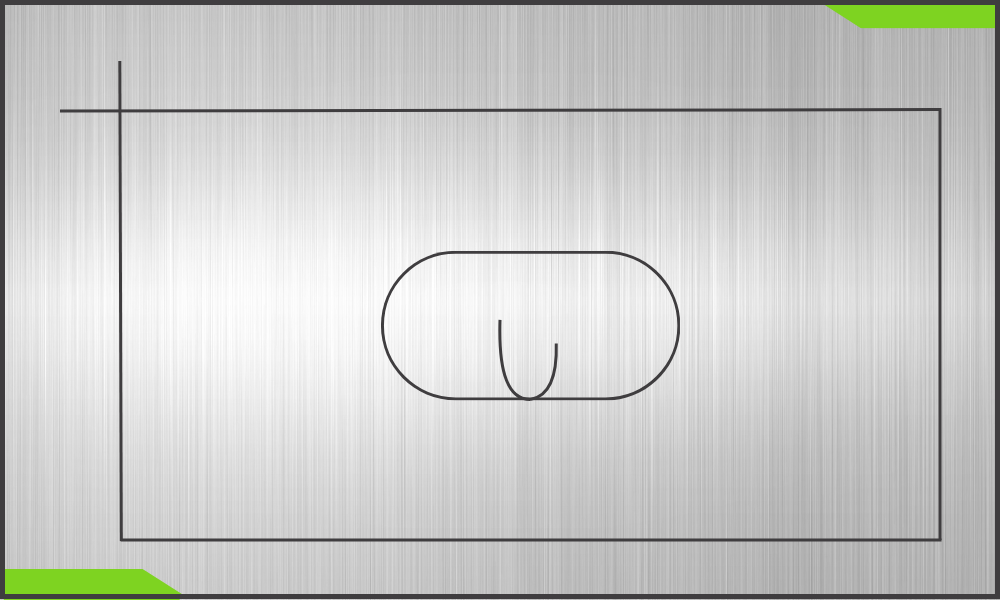

Lead-in & Lead out

Nest&Cut will first set lead-in and lead-out for each contour. It will avoid placing lead-ins too close to other parts to allow a good quality result. It will also take advantage of the parts geometry: while round contour will receive arcs-based lead-in, straight outer contour can receive a lead-in in continuation of a segment in an angle.

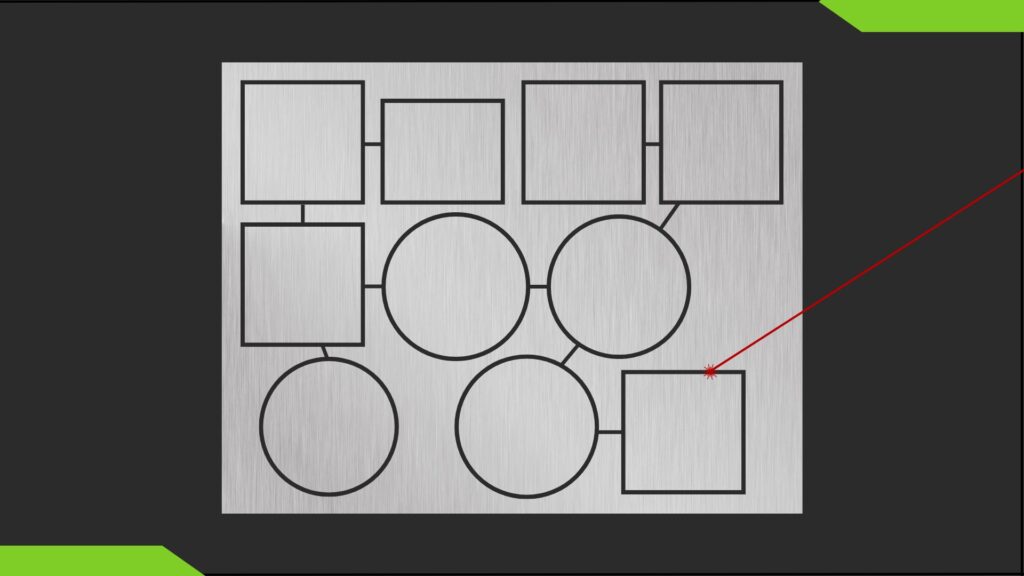

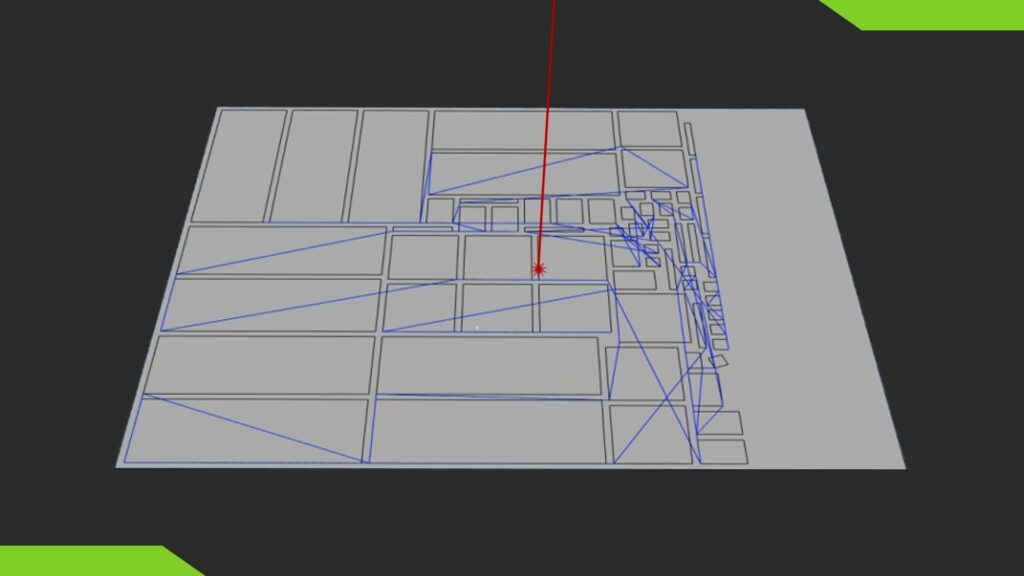

Optimized sequence

Nest&Cut will then sequence all the cutting trajectories of the parts.

This consists in defining an order that will be quick to cut, and avoiding round trips. This also requires considering a number of constraints, such as cutting a part placed in a hole before the hole of the enclosing part.

Some additional trajectories are also added, such as vaporization trajectories or fast traverses between different cutting trajectories.

A translation generated for many machines

Once the sequence result is calculated, Nest&Cut writes code dedicated to the selected machine.. such as Amada, Bystronic, Cypcut, Ermaksan, Esab, or Hypertherm machine etc. Standard format suchs as GCode, LinuxCNC and ESSI formats are also supported, as well as DXF accepted by most NCs. We are adding more and more supported machines every months.

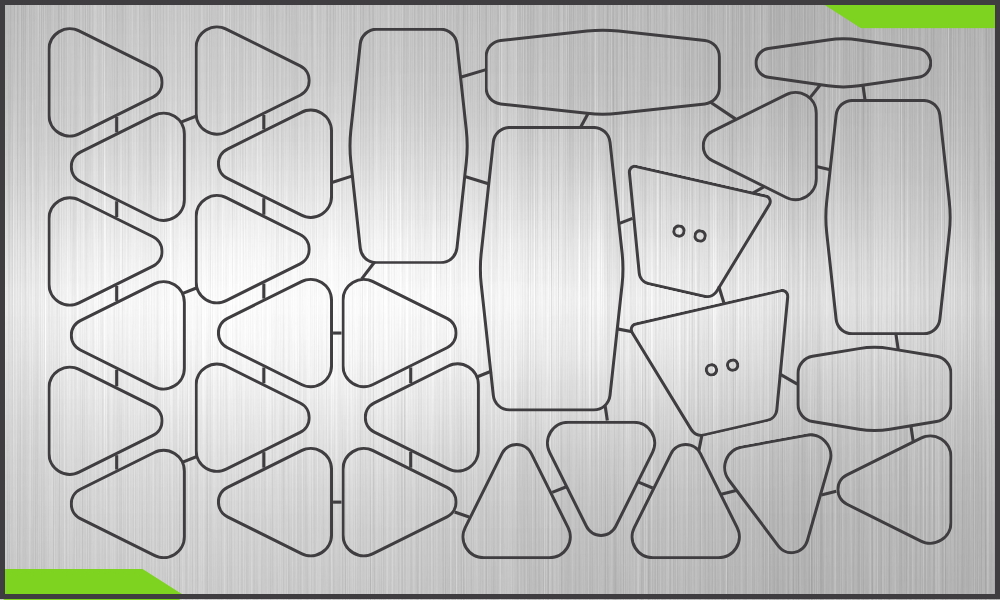

Bridges & Micro-joints

Two features to optimize your production according to your technological specificities.

Bridges help you reducing the number of leads-in and save time. They are usually used with thick materials where lead-ins take more time and particularly well suited for plasma and oxy cutting machines.

On the contrary, micro-joints are tailored for thin materials especially for laser cutting machines. Micro-joints are small portion of a part’s contour where the material is left uncut to keep the part attached to the skeleton. It is however small enough so that parts can be separated easily by the operator when unloading.